1. Maintaining an aircraft engine is not only complex and time consuming but also very expensive. Aircraft maintenance costs typically account for around 10% to 20% of the operating costs. Aircraft maintenance involves actions intended towards ensuring inherent safety, reliability and restoring the item to its operational condition. The maintenance actions are subdivided into inspection and on condition checks, overhaul, servicing, modification, and repair. Every maintenance activity comprises of a fixed cost element and variable costs. Improved life estimates of critical components are therefore essential to facilitate reliable maintenance plans and lowering the maintenance costs.

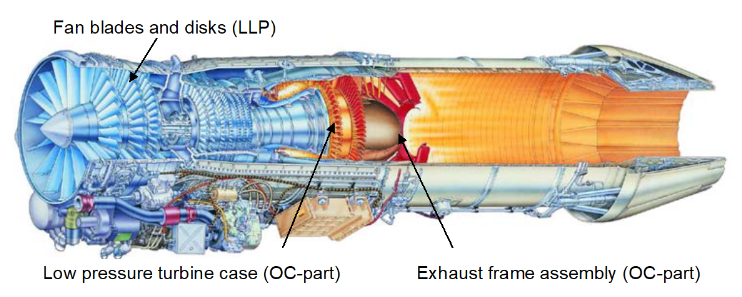

2. Aircraft engine components are commonly classified into three categories, life-limited parts (LLP), on condition parts (OC) and consumables. One of the key elements in aero engine maintenance is to identify the remaining useful life of critical and lifed engine components and to use this information for maintenance optimization. LLPs have a fixed lifespan and must be exchanged when they have reached that limit since they are safety critical (i.e. any failure of that part could cause an engine breakdown so serious that it would cause the aircraft to crash). OC parts are “stochastic” parts that are approved for further use as long as their condition is within approved limits.

3. Aircraft engines are normally brought to the workshop for two reasons: Unscheduled maintenance and routine/scheduled maintenance. Scheduled maintenance occurs at predefined intervals when the engine components are still operational. Unscheduled maintenance activities include troubleshooting, removal and replacement of defective components, repairs, engine test-bed runs etc during inspections. The aircraft technicians need to decide which components to maintain (LLPs and OC).

4. Deciding to change an LLP is comparatively uncomplicated since its remaining life is deterministic and defined by a numeric (quantified) life limit. There are well-defined rules for number of cycles allowed before a particular LLP needs to be maintained or replaced. The number of cycles a LLP has consumed depends on the circumstances and operating conditions under which the engine has operated. For example, an engine exposed to air-to-air or air-to-ground missions is likely to consume more life than an engine on reconnaissance missions. Similarly, an engine exposed to combat mode and higher loads, higher temperatures and pressures are likely to consume more cycles than an engine that is used for transportation profile.

5. OC parts on the other hand are evaluated based on the maintenance manual containing approved deviations and remaining life/ hours for OC parts are never estimated. The remaining useful life for OC parts is calculated based on historical failure data. Based on its condition the component is either cleared for operations or withdrawn from service. This uncertainty or inability to estimate accurate RUL of OC Parts leads to either removal of the component much before the actual expiry or continuation of the component after its expiry which will have a significant impact on the flight safety and maintenance costs. In addition to this, the maintenance planning lacks Optimization of Aero Engine Utilization through Improved Estimation of Remaining Useful Life (RUL) of On Condition (OC) Parts There is, therefore, a need for improved life estimates for the OC parts to be incorporated in the maintenance planning model for best utilisation and reliability of operations.

6. LLP Components Management: The life consumption calculations are important as they influence the status of the LLPs. Some of the leading OEMs have evolved a methodology called as Life Tracking System (LTS) to calculate the life consumption of life-limited parts (LLP). The calculations draw on engine parameters and data from each mission to determine how many life cycles have been consumed by each mission. In event of nothing unexpected and unforeseen, the LTS calculation predicts the next maintenance interval with high accuracy. Even though LTS reduces the uncertainty about the load signature for each individual component, however the shortcoming is that the variation in consumption rates between OC components is found to increase, as a consequence it is difficult to exactly estimate the number of flight hours remaining before the next maintenance. LTS method provides much better information and control over the life consumption of the LLPs, as long as the engines operate with the same flight profiles. LTS however is unable to calculate the life consumption for OC parts, and thus their remaining life has to be estimated by better and improved methods. Better life estimates for OC parts would maximize the residual RUL thereby minimize the maintenance downtime, maintenance costs thereby improve the availability and readiness of the fleet.

7. The challenge of OC parts: OC parts are the category of components in an aircraft engine that are evaluated according to their component maintenance plan (CMP). The Standardized Replacement model has been proposed considering not only historical data which is being used currently but also the data acquired from flight analysis which includes flight profiles, analytical data which contains various parameters of the engine. Based on this integrated data a standard for different OC Parts is mentioned in the Component Maintenance Manual (CMM) made by OEM. This approved standard is considered as Standardized Replacement Model and is regularly modified or upgraded according to the operations and modifications that the engine undergoes during its Service as part of Continuous Improvement. The remaining flight hours for an OC part are never estimated, an OC part is changed when needed; the decision is based on several factors, such as cracks, discoloration, and other fault modes that indicate the health of each OC component. In the current maintenance process the actual status of OC parts can only be identified through inspection and non-destructive testing.

8. The maintenance as per the Standardized Replacement model requires an OC Part to be periodically inspected and checked against the physical standard mentioned in the manual to determine whether it can continue in service or not. The purpose of this is to

remove the part before its failure during various operations. This model helps to determine which components should be replaced at an actual maintenance occasion based on the data acquired. This model is able to calculate the optimum balance between the remaining life of the engine components and the costs for each maintenance interval versus the cost of the component and their exchange. This creates a maintenance plan with as few maintenance events as possible without compromising on safety. Estimation of RUL for OC Parts is improved with this model as it uses a classification method that classifies the components into different life length groups depending on the fault modes and the status of components. The estimated RUL for each component could then be used to indicate a more accurate RUL of each OC Part so that the component can be effectively used for various operations. A replacement model that uses better life estimates for OC parts would also make it easier for technicians to follow a more reliable replacement schedule, as well as providing a better support system and ensure that correct maintenance activities are performed at each maintenance interval. A desirable effect would be to eliminate at least one maintenance service due to longer intervals between maintenance events.

9. Prognosis aggregation from component to system: Both LLP and OC parts are required for engine operation. To increase the reliability of the optimization results, all components liable to maintenance in the engine need to be incorporated, independent of whether they are LLP or OC parts. The Life Tracking System (LTS) has resulted in much better information about and control over the life consumption of the LLPs. Better information regarding life consumption for the LLPs improves the input data for the mathematical replacement model, leading to more reliable optimization results. LTS however is unable to calculate the life consumption for OC parts, so it is still necessary to estimate their remaining life OC parts. Improving the remaining life estimation for an OC part helps to improve the reliability of the complete subsystem (module), as an improvement affecting any component improves the planning for the complete subsystem. It is however important to evaluate the robustness of the Standard replacement model (i.e. how sensitive the model is to “errors” in the estimates of remaining life). Life estimates for OC parts can be binary (“ok/not ok”), a few possible values, and a continuous variable in a specified range, or even data in an algorithm. This will probably vary from component to component, but are key issues in resolving the problem of developing better life estimates for the OC parts in an aircraft engine.

10. Introduction of prediction methodologies and techniques for calculation of RUL of Aero engine components and parts helps timely identification of departures from the expected performance. It is found that improved calculation of life consumption of an LLP using LTS and improved estimation of RUL of OC Parts using Standardized Replacement Model improves the Optimization of Aero Engine Utilization.